The Single Best Strategy To Use For DTF Transfer

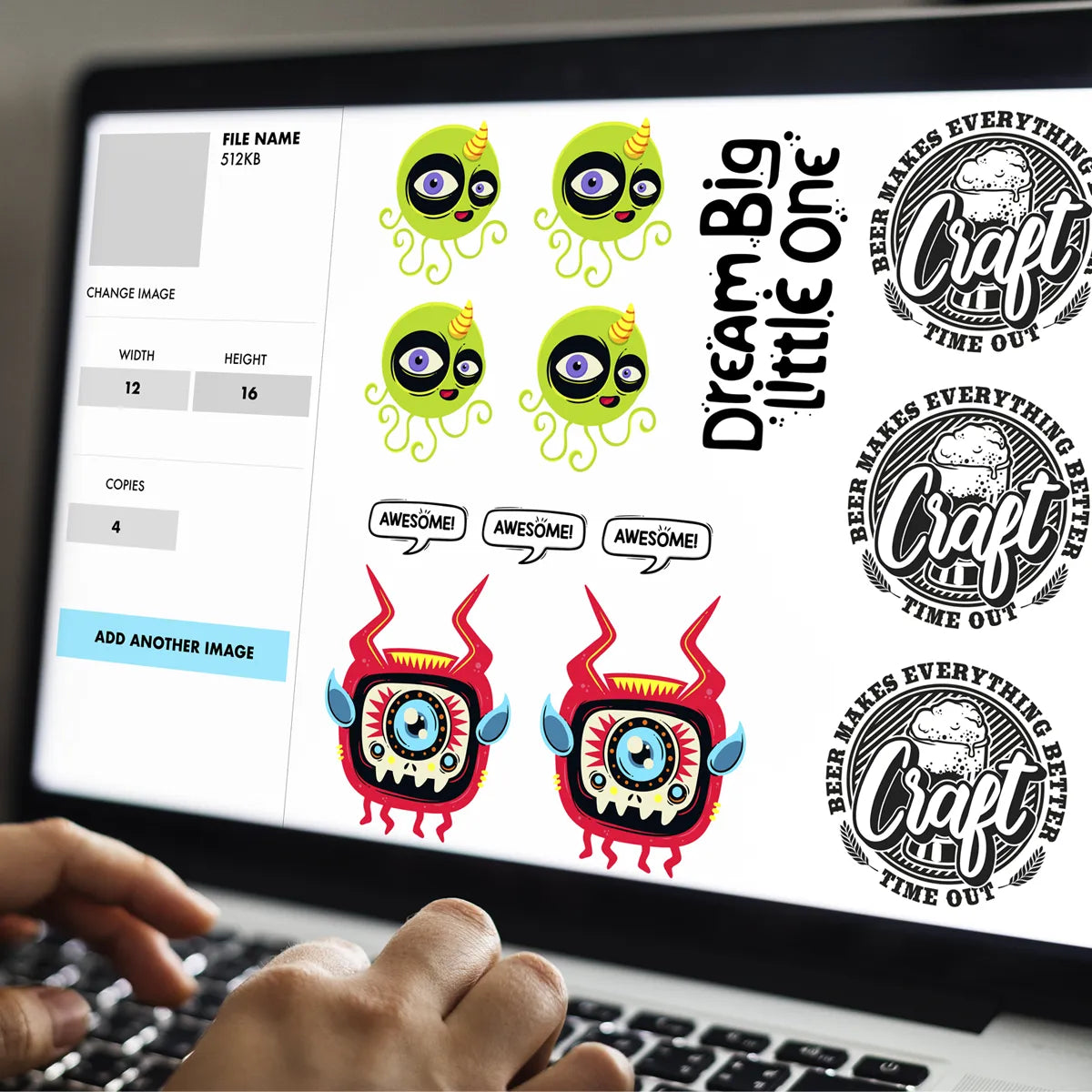

The transfer approach is completed applying heat and force. after the PET film is positioned onto the material, the applied heat and stress allow the ink to pass through the PET film and on to the material.

Impact of structure size on material drape: Printing a large design and style on a cloth can have an affect on its adaptability and drape. to take care of the fabric’s normal motion, you might desire applying smaller prints on your shirts and sweats.

If you’re looking for a Expense-productive and versatile way to supply higher-top quality clothes, warm Printz direct to movie heat transfers may very well be the solution you need.

The location of the warmth transfer is equally important, because it right impacts the visibility and equilibrium of the design. Heart chest placements attract focus and are perfect for charming graphics, when remaining chest placements exude class and in many cases are favored for company branding.

DTF printing is really a hugely satisfying process for both businesses and personal use. During DTF transfer, you'll find selected factors that must be considered.

This suggests you are able to keep the stock lean and stay clear of the risk of overstocking or understocking. DTF warmth transfers also help you present you with a broader number of items without the need to spend money on a substantial stock upfront.

Powder: right after printing, although the ink continues to be soaked, a warm-melt adhesive powder is applied to the printed aspect of the movie. This powder sticks to your damp ink and may finally bond the look to the fabric.

A good powder adhesive ensures that the ink bonds effectively with the transfer movie, providing toughness and adhesion.

Print location - This refers back to the site about the garment or even the classification of print (left upper body print, whole back again print). Placement and print spot will vary in the print site.

What are some great benefits of DTF transfers? DTF transfers boast elasticity and durability. They produce high-resolution and intricately in-depth prints which might be bursting with vibrancy. they supply the comfort of hot or warm peels and involve nominal urgent time. in comparison to other techniques, DTF printing needs fewer artwork preparing, as You will find a diminished necessity for rasterization or destructive space. Our personalized DTF transfers only mandate a raster file that has a recommended resolution of 300 DPI (for the most beneficial ends in quality) but will accommodate both of those raster and vector formats.

Yellowing of adhesive or waffle texture about the provider is possible and standard; this may not have an impact on application.

three. Applying the Adhesive: A powder adhesive is applied to the soaked ink soon after printing. This adhesive enables the look to bond with The material when warmth pressed.

Professionals seeking a lot more insights can check with “DTF this means in printing your distinct manual” and make the most of the "DTF transfer placement manual" and "ideal DTF warmth push configurations guidebook" for very best final results.

1. creating for DTF: the initial step in the DTF transfer process is developing your layout. It’s important to use high-resolution pictures to be certain your final print is crisp and distinct. DTF transfers enable for click here intricate patterns with high-quality aspects, so you can be as creative as is possible.